Yield Optimization and Validation

Which wind turbine optimization measures are worth the money? Which increase in annual energy production can we reasonably expect after optimization?

These are the questions which are most relevant for our customers. We answer them by providing independent validation results with site-specific big data software solutions and by giving insight into our track record database of validated optimization projects.

Since 2018, we have contributed to the optimization of more than 280 MW of wind farms in Sweden, Finland, Germany and Ireland.

Prior to the analysis, the operating data of the wind turbines is reviewed and processed to account for air density fluctuations, turbulence intensity fluctuations, the wake flows of neighbouring WTs, changes in yaw offsets and the anemometer transfer function.

The parallel application of several, independent data analysis techniques based on python and VBA allows us to cross-check our findings. The validation methods applied by us today are listed below:

1. Internal ex/post analys for solitary wind turbines:

2. Power-to-power evaluations with adjacent wind turbines:

3. Toggle Analysis: The optimization control is switched ON & OFF continuously in short time steps.

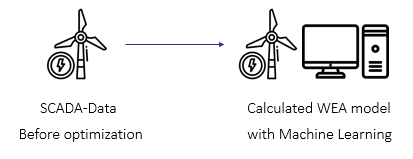

4a. Machine Learning-Analysis, Step 1: A ML-model is created and trained on the the unoptimized WT operation dataset

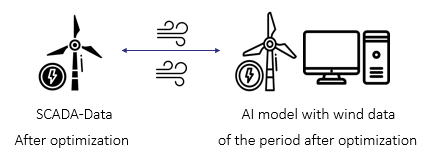

4b. Machine Learning-Analysis, Step 2: The trained ML-model is used to simulate the operation of the unoptimized WTG under the wind conditions after the optimization period and compared to the measured energy output of the optimized WT.

We provide an independent validation report for our customers on request for internal and external communication and to supports them in optimizing their entire wind farm portfolio.

A selection of wind turbine optimization options are presented below:

Yaw Control System

The yaw control system makes sure that the hub orients itself precisely and rapidly into the predominant wind direction. An optimal function of the control system is however not always ensured (not even by renowned original equipment manufacturers). There is potential for wind turbine optimization.

Pitch Control System

The pitch control of the rotor blades shall guarantee that the rotor blades are always oriented at an optimal angle to the wind flow. In reality, the pitch system is often subject to major deficits. This provides interesting options for profitable software updates.

Rotor Blades

The aerodynamic profile of the rotor blades should be designed in a way that enables the wind turbines to transform a maximum share of the incoming wind energy into the rotation energy of the rotor. The energy efficiency of wind turbines with sub-optimal rotor blade profile can be enhanced via aerodynamic modifications.

Park Optimization

Wake deflections via yaw offsets or sinusoidal pitch angle movements decreased wake losses and optimized the total wind park production in wind tunnel tests, simulations and in commercial applications

Permit

Permit obligations for wind turbines can cause considerable production losses:

• Obligations regarding noise and shadow emissions

• Obligations regarding icing protection

• Obligations regarding nature conservation (birds and bats)

• Obligations regarding turbulence-induced loads (sector management).

There are legal options available to reduce the production losses related to all of the aforementioned permit obligations.